When you’ve selected to head the agile path on your IoT construction venture, how do you you’ll want to’re a success? We’ve narrowed it right down to 10 key steps that we observe at Very to get our purchasers’ largest agile IoT initiatives absolutely operational.

1. Validate Your Assumptions and Outline Venture Constraints

Even supposing we observe agile IoT venture paintings at Very, we’re now not allergic to documentation and construction necessities. What’s maximum necessary in collecting the ones necessities is that we don’t get to the purpose the place we’re losing time validating untimely assumptions.

For segment one, the very first thing we do is dig into our riskiest assumptions — the ones assumptions that, if they’re invalidated, will turn the ROI equation the other way up. With agile IoT initiatives, we run experiments to check the ones assumptions, like buyer interviews, attaining out to production companions, and extra.

The second one a part of this degree is figuring out the ROI of the venture, which is able to contain collecting gross sales projections, doing marketplace analysis, and working out your consumers’ worth level thresholds. We’ve discovered that if you’ll establish one of the vital value parameters for the tool that you just’re construction or the services and products that you just’re growing, this may occasionally assist tell choices down the street and can stay you from having to do primary revamps and part swap-outs past due within the sport.

2. Construct an IoT Product Building Roadmap

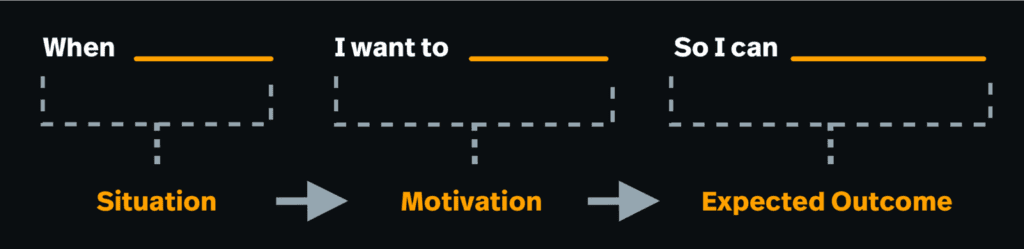

To construct a product construction roadmap, we take the wishes, needs, and needs we’ve established for our customers all the way through our Technique Dash and use them to jot down process tales. Task tales assist us to outline a given scenario, a person’s motivation for appearing inside that scenario, and the anticipated end result of the motion.

Then, we create a workflow map that is going thru each and every characteristic in a tool or product to peer all of a person’s conceivable paths, accounting for each “satisfied paths” (when customers do what they’re meant to do inside your product) and “unhappy paths” (when a person doesn’t total the anticipated motion, like typing an invalid password).

As soon as we now have a powerful workflow map that will get everybody at the identical web page (actually), we create playing cards in our venture control device (we use JIRA). The playing cards escape person process tales, element any attainable blockers, and determine who’s running on what. Our engineers use the playing cards to head thru a tale pointing procedure, the place they estimate the complexity of each and every characteristic and what kind of they are able to accomplish inside a given period of time. That is what is helping us to make correct projections about how lengthy issues will take and what we’ll be capable of get executed.

three. De-Chance Your Hardware

Step 3 is after we if truth be told get started construction issues and hammering out the fundamentals. The purpose here’s to get rid of unknowns across the hardware design. We resolution questions like:

- Is it conceivable to measure/keep watch over X with a suitable degree of accuracy?

- Is it conceivable to obtain wi-fi communique within the anticipated working setting?

- Is the anticipated invoice of fabrics value possible from a budgetary standpoint?

four. Imitate Your Finish Product

Now that the root is about, it’s time to make this tool do its process. We name this degree “imitation” as a result of, for hardware, we’re looking to create a tool that can imitate the best way the top product will paintings. It must be capable of reliably perform, determine a community connection, and test for firmware updates.

The device, in the meantime, must be capable of imitate the interactions with the tool. This contains getting the OTA firmware replace procedure in position since having person builders manually updating firmware can introduce useless chance.

five. Construct a Complete Prototype

When we’ve effectively imitated the top product, it’s time to simulate it via construction a complete prototype. We commence plugging in genuine parts with the purpose of having the tool to make use of the true CPU structure paired with the general code on a construction board.

By means of the top of this degree, the prototype must be absolutely hooked up to the internet. We must be capable of ship knowledge to and obtain knowledge from the tool, together with IoT firmware safety updates. The firmware and device must be able for manufacturing (however almost definitely now not feature-complete) at this degree.

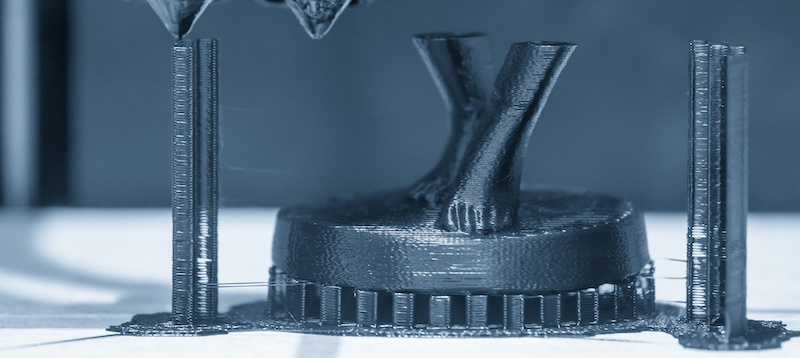

6. Entire a Micro-Facturing Run

When we’ve constructed our first prototype, it’s time to start out replicating it in what we name a micro-facturing run. The purpose is simply to create sufficient merchandise in order that each engineer at the venture has one to paintings with, so that they’ll generally be hand-soldered and Three-D-printed. From a hardware standpoint, that is after we’ll get started making choices about enclosures and fabrics. We’ll get started doing such things as sending for ultimate component research and working fashions for checking out high-stress spaces within the mechanical design. After the ones checks, we begin to get a hold of some answers or fashions to relieve the ones high-stress issues.

An important a part of this step is that we’re in point of fact beginning to take into accounts how this tool goes to act within the wild. We’re looking to see if there’s the rest basically flawed at this degree. We all know that we’re able to transport on after we really feel relaxed that lets put one thing extremely very similar to this tool and within the palms of the customers in a beta release.

7. Release Your First Production Run

By the point you release your first production run, you must really feel assured sufficient with the choices made to this point to supply round 50–100 units, relying at the context of the venture. It’s time to get a pilot team engaged, finalize the board format, and optimize the device infrastructure.

At this level, the largest drivers of exchange shouldn’t be new mechanical necessities. They must be the real customers and the way the product is behaving on this planet. Moreover, at this degree, we take proactive steps to make certain that the true production run will pass easily. We make estimations for the general invoice of fabrics, test with our production companions concerning the quantity they’ll be capable of take care of, and ensure we’re taking the correct steps to get the product qualified via the related regulators.

We’re able to transport on from this degree after we’ve won powerful comments from our pilot team and feature made changes as wanted.

eight. Do Your “Actual” Production Run

By means of step 8, issues are getting thrilling. For a “genuine” production run, we advise generating about 1,000 units to accomplish preliminary person checking out, product coaching, and onboarding. From a hardware standpoint, when there are units out on this planet we’re in a position to start out validating longevity problems (e.g., is the glue we used dressed in out?) We begin to see the true affect of temperature and environmental results on those units. We all know that we’re able to transport on after we’ve won further cast comments, and almost definitely had a few “aha!” moments alongside the best way.

nine. Move to Marketplace with Your Ultimate Production Run

Once we succeed in step 9, the go-to-market production run, we’re able to transport ahead in a large manner. The device and firmware had been appearing neatly for some time, we’re assured in our hardware possible choices, and the theory of bringing loads of those units on-line immediately isn’t frightening as a result of we’ve accounted for attainable problems forward of time. Getting rid of those worries provides us time on this degree to optimize for economies of scale.

10. Discover the Energy of Virtual Twins

With the product out on this planet gathering knowledge thru sensors and sending it to the cloud, we now have a wealth of knowledge we will be able to use to create a virtual dual, a digital style of the product that takes real-world stipulations under consideration. Virtual twins can be utilized for checking out, predicting and diagnosing failure, and experimentation for the following model of the product.

Agile IoT initiatives within the Actual Global

One in every of our favourite quotes about running on IoT initiatives comes from Very’s personal Device Engineering Observe Lead, Daniel Spofford:

“Not anything beats the true global. The true global is messy. That’s why agile IoT is related and important.”

Once we created those steps, our focal point was once on getting merchandise within the palms of testers and customers as temporarily as conceivable, then the usage of the comments from the ones cycles to tell the improvement procedure.

The secret to meaking all of those steps if truth be told paintings, despite the fact that, is communique and cadence. At Very, we do per 30 days free up making plans, weekly sprints, day by day standups, and weekly retrospectives the place we establish what went proper and what didn’t in order that we will be able to make changes. Each unmarried week we’re training discovering ways in which we will be able to paintings higher in combination.

Agile IoT is a adventure of one,000 tiny steps. What issues maximum is that everyone is taking the ones tiny steps in combination.